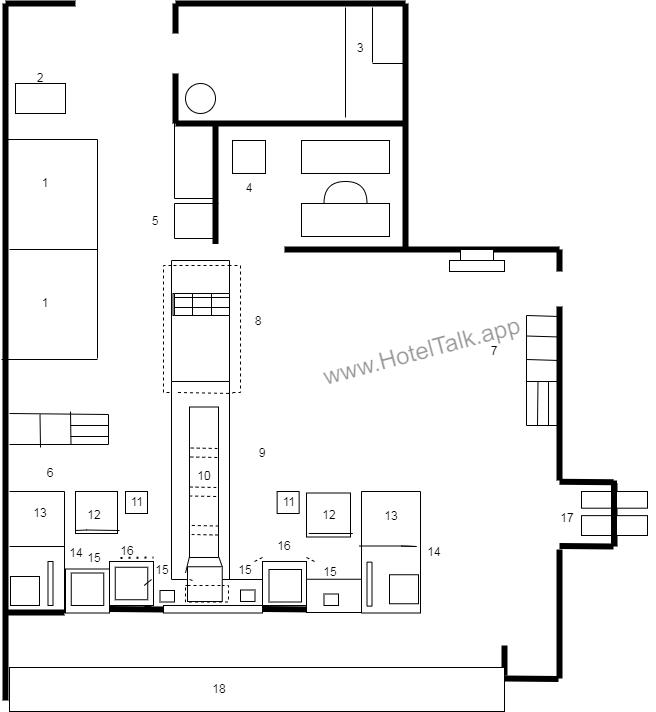

All products, equipment and supplies must conform to strict specifications. The call-order layout is designed in a double T layout for highly efficient i production, with a conveyor-broiler supplying dual preparation areas backed up by microwave ovens for cheese melting, deep fryers for chips and onion rings, and a conveyor toaster. The system aims to supply meals to call-order within 30 seconds. Ten to 15 counter staff are linked by microphone to the kitchen area in which there may be up to 25 staff working at the same time.

Key

1 Cold storage

2 Soda factory

3 Lye tank for broiler

4 Office

5 Wash hand basin

6 Double sink

7 Triple sink

8 Conveyorised broilers

9 Preparation bench

10 Microwave ovens

11 Refrigerated well

12 Shake machine

13 Cuber& drink preparation

14 Drink dispense

15 Holding sections

16 Double bank fryers

17 Pass-through waste & tray

Typical hamburger production layout